Excellex Inspection Inc is dedicated to maintaining the highest standard in both quality, health and safety performance in the services that we deliver to our clients. We believe that NDT plays a crucial role in everyday life. We assist clients to prevent environmental impacts from their operations and protecting the environment and the public are always first of mind for all of our technicians.

Excellex Inspection Inc regularly conducts internal audits on all of our technicians, both corporate and contractor, to ensure that our technicians demonstrate and maintain an active commitment to both quality and safety.

QUALITY…DOING IT RIGHT THE FIRST TIME.

Providing the highest quality of service is a core value of Excellex Inspection Inc.

We believe that quality assurance and integrity of critical equipment and facilities are instrumental in the protection of the environment, public health, and life. We understand that managing quality in the NDT industry means that we must first understand the specific quality expectations for our clients and then put a proactive plan in place to meet and/or exceed those expectations.

By definition, Quality Control (QC) refers to the process and the procedures used in creating the NDT product or services delivered. This is generally undertaken by subject matter experts (SME’s) to meet the clients and code requirements.

NDT Procedures

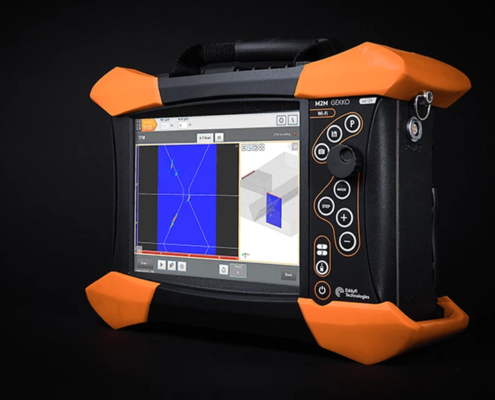

Excellex Inspection Inc has invested heavily in the production of code compliant NDT procedures for performing each NDT method systematically and to the best industry practices.

Our NDT procedure manual contains the latest updated procedures and include all applied ASME V discipline requirements.

- Excellex Inspection Inc’s ASME V applied procedures have been approved by the jurisdictional bodies in Alberta (ABSA); British Columbia (BC Safety); and Saskatchewan (TSask).

- CSA scopes are also developed by discipline with procedural content in support of our W59 and CSA Z662 customer requirements.

- Where specifically required, tailored procedures can be developed by our CGSB, ASNT and SNT-TC-1A Level 3 for any discipline; should there be a need to do so.

NDT procedures are the core of Excellex Inspection Inc’s QC system and ensure a controlled and repeatable NDT application that satisfies both our customer’s inspection and code requirements.

Quality Assurance and Quality Control

Regularly scheduled field and report auditing is conducted to ensure that technicians are performing and providing our clients with high quality information that meets/exceeds all of their requirements. Excellex Inspection Inc also has an extremely robust SNT certification program which verifies levels of competency in technicians who are certified in various NDE disciplines.

QA and QC work as one and BOTH must be performed to ensure that the NDT deliverables meet or exceed our customer’s quality requirements.

Making it Happen

How does Excellex Inspection Inc ensure the highest level of quality in our work?

We employ key personnel that drive the entire process forward

- A Level 3 subject matter expert to oversee all technical aspects of quality

- A full time dedicated auditor to meet the requirements of our quality program for NDE

- A Quality Manager who ensures adherence to quality program requirements

- An ISO 9000 compliant program to ensure best industry practices

A CULTURE OF SAFETY

Excellex Inspection Inc fosters a culture of safety in which everyone believes all accidents and injuries are preventable and all employees understand their accountability for maintaining a safe and healthful workplace. We are committed to ensuring the highest regard for the health, wellness, and safety of it’s employees, contractors, customers, and the public. The work and schedule is never so urgent or important that the work cannot be performed safely.

Through collaboration and cooperation between all levels of the company, Excellex Inspection Inc management makes sure the company meets or exceeds industry standards and complies with applicable occupational health and safety legislation.

Excellex Inspection Inc supervisors are held accountable for the health and safety of their workers. This includes ensuring personnel receive proper training both for machinery and equipment, and work practices and procedures. Through working in compliance with both legislation and established workplace practices, our employees protect not only their health and safety, but the health and safety of others.

Elate Head Office

- 1028 Garfield Ave, Jersey City, New Jersy 07304 - USA

- +1 (800) 433 544+1 (800) 433 545

- support@elateaccount.com

- Mon - Sat 8.00 - 18.00.